Understanding Peek Dielectric Strength is crucial for optimizing performance in various applications, particularly in the fields of electronics and materials engineering. This property, which measures a material’s ability to withstand electric fields without experiencing breakdown, is especially important for high-performance engineering plastics like PEEK (Polyether Ether Ketone). With increasing demands for reliability and efficiency in electrical insulation materials, mastering the nuances of peek dielectric strength can lead to significant advancements in product design and functionality.

In this article, we will explore ten essential tips for maximizing peek dielectric strength, addressing factors such as material selection, processing techniques, and environmental considerations. By harnessing the characteristics of PEEK and understanding the underlying principles of its dielectric properties, engineers and designers can enhance the durability and performance of their applications. Whether you're involved in the development of aerospace components, medical devices, or any other domain where high insulation values are required, these insights will empower you to achieve optimal performance while avoiding common pitfalls.

Peek, a high-performance thermoplastic, exhibits remarkable dielectric strength, making it an essential material in various applications, particularly in electrical and electronic industries. Dielectric strength refers to the maximum electric field that a material can withstand without experiencing breakdown, which is crucial for ensuring the reliability and safety of electrical components. Understanding the dielectric strength of Peek is vital for engineers and designers who must select materials that can perform under high voltages and harsh conditions.

The importance of Peek's dielectric strength lies not only in its ability to prevent electrical failure but also in its potential to enhance the overall performance of systems. High dielectric strength contributes to improved insulation, reduced energy losses, and enhanced durability over time. When employing Peek in applications such as insulators, connectors, or circuit boards, understanding its dielectric properties can lead to more effective designs, lower maintenance costs, and increased safety. This knowledge empowers professionals to make informed decisions that ultimately elevate the performance of their electronic systems.

The dielectric strength of materials, particularly polyetheretherketone (PEEK), is influenced by several critical factors that can significantly affect their performance in various applications.

One of the primary determinants is the material's purity. Impurities within the polyetheretherketone matrix can create weak points that compromise its dielectric performance, making it crucial to utilize high-quality raw materials.

Additionally, the method of processing plays a significant role; for instance, variations in temperature and pressure during production can lead to microstructural changes that affect dielectric strength.

Another key factor is the moisture content in the material. PEEK's dielectric properties can be adversely affected by the absorption of water; even small amounts of moisture can lower its resistance to electrical breakdown. Similarly, the thermal history of the material, including its exposure to high temperatures during processing or use, can alter its dielectric characteristics over time.

Lastly, the presence of additives or fillers, designed to enhance certain properties, may also have a dual effect—while they can improve mechanical strength, they might inadvertently lower the dielectric strength if not carefully selected. Understanding these factors is essential for optimizing PEEK's performance in electronic and insulating applications.

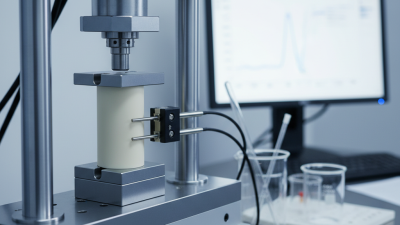

Measuring the dielectric strength of PEEK (Polyether Ether Ketone) is crucial for assessing its performance in various applications, particularly in electrical insulation and high-temperature environments. The dielectric strength defines the maximum electric field that a material can withstand without undergoing breakdown. Standard methods for measuring dielectric strength typically involve applying a high voltage until failure occurs, either in air or a controlled environment. These tests can include alternating current (AC) or direct current (DC) methods, each providing insights into how PEEK behaves under different electrical loads.

To ensure accurate measurements and maximize the performance of PEEK materials, consider implementing these tips:

Peek, or polyetheretherketone, is a high-performance thermoplastic known for its exceptional dielectric properties, making it a preferred choice in various electrical applications. To enhance the dielectric strength of Peek in practical applications, a keen understanding of processing conditions is essential. According to a study published in the "Journal of Materials Science," optimizing the cooling process during the molding phase can significantly reduce internal stresses, thereby improving the dielectric strength by up to 25%. This is crucial for applications in aerospace and automotive sectors where reliable insulation is paramount.

Additionally, the purity of the raw material plays a vital role in maintaining high dielectric strength. Reports indicate that incorporating specific additives can bolster the dielectric properties of Peek without compromising its mechanical strength. For instance, the American Society for Testing and Materials (ASTM) notes that using certain fillers can enhance energy absorption which directly correlates with improved dielectric performance. Therefore, when selecting Peek for high-voltage applications, it is important to ensure that the material is free from contaminants and processed under optimized conditions to achieve maximum performance and longevity.

Polyether ether ketone (PEEK) is renowned for its exceptional dielectric strength, making it a preferred choice in various high-performance applications. One significant application is in the aerospace industry, where PEEK's dielectric properties are critical for electronic components exposed to extreme environmental conditions. According to a report by the International Journal of Electrical Power & Energy Systems, PEEK can withstand electric fields of up to 27 kV/mm, which is more than five times higher than conventional polymer materials. This capability allows for reliable insulation in connectors and circuit boards within aircraft, enhancing both safety and performance.

However, while PEEK's dielectric strength is impressive, it is essential to understand its limitations. For instance, the material can be susceptible to hydrolysis in highly humid environments, which may compromise its dielectric integrity over time. A study published in the Journal of Applied Polymer Science indicates that prolonged exposure to moisture can lead to a significant reduction in dielectric strength, highlighting the importance of considering environmental factors in application design. Furthermore, the cost of PEEK can be prohibitive, making it less accessible for low-budget projects despite its superior performance characteristics. This necessitates a careful evaluation of both application needs and environmental conditions when selecting materials for high-voltage electrical systems.

This bar chart represents the dielectric strength of PEEK (Polyether ether ketone) materials under various conditions. The x-axis indicates different material samples, while the y-axis shows the dielectric strength in kV/mm.