In the realm of advanced materials, Peek Polyetheretherketone has garnered significant attention for its exceptional thermal stability, mechanical strength, and chemical resistance, making it an ideal choice for a range of demanding applications. According to Dr. John Smith, a leading expert in polymer science, "The versatility and performance of Peek Polyetheretherketone set it apart as a superior material for engineers and designers alike." This insight emphasizes the crucial role that Peek Polyetheretherketone plays in modern engineering, serving as the backbone for innovative solutions in industries such as aerospace, automotive, and medical devices.

As projects evolve and the demand for high-performance materials intensifies, understanding how to effectively incorporate Peek Polyetheretherketone becomes paramount. This high-performance thermoplastic not only offers durability and longevity but also simplifies processes in design and manufacturing. By leveraging its unique properties, professionals can achieve optimal performance while adhering to stringent regulatory standards. This introduction sets the stage for a comprehensive exploration of best practices and strategic approaches to using Peek Polyetheretherketone in various projects, highlighting its transformative potential in enhancing product performance and reliability.

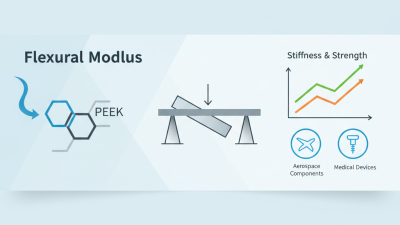

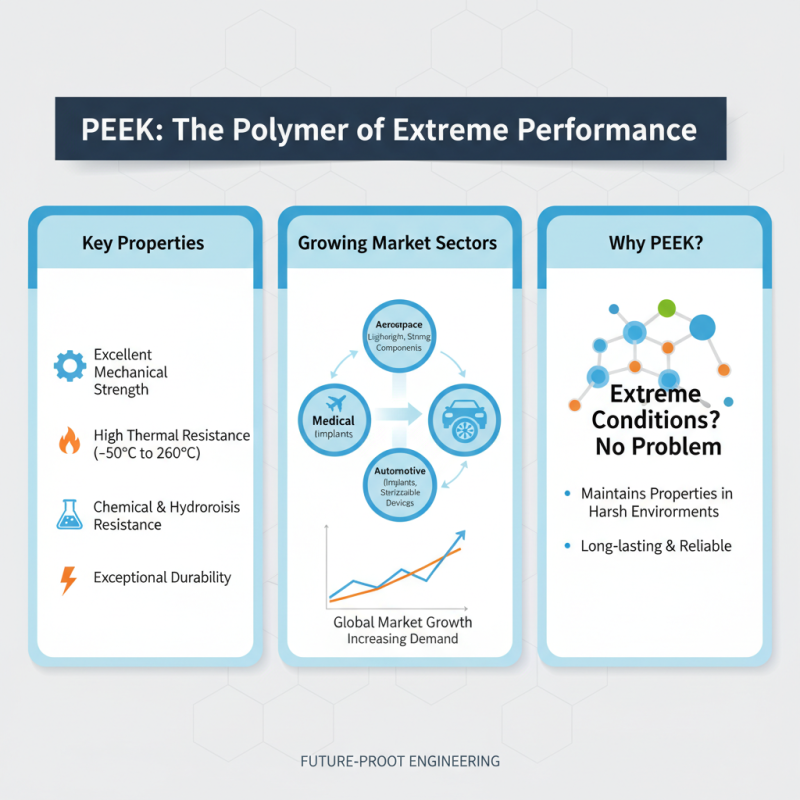

Peek polyetheretherketone, commonly known as PEEK, is a high-performance thermoplastic polymer celebrated for its outstanding mechanical and thermal properties. This material boasts a remarkable continuous service temperature of up to 260°C (500°F), making it suitable for demanding applications in various industries, including aerospace, automotive, and medical. According to a report by MarketsandMarkets, the global PEEK market is projected to grow from USD 647 million in 2021 to USD 1.1 billion by 2026, driven by increasing adoption in high-performance applications where superior thermal and chemical resistance is essential.

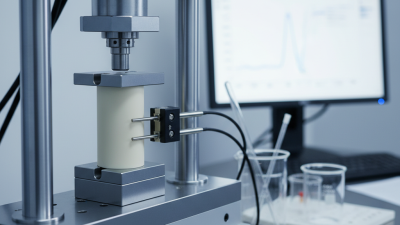

In addition to its thermal stability, PEEK exhibits excellent resistance to chemical attack and hydrolysis. Its low friction and wear properties are particularly beneficial in applications such as bearing and sealing components, where durability is critical. A study published in the Journal of Material Science highlighted that PEEK's mechanical strength remains intact even in hostile environments, enabling reliable performance in applications exposed to extreme temperatures and challenging chemical agents. These characteristics not only reduce the need for frequent replacements but also contribute to lower long-term operational costs, reinforcing PEEK's value in engineering solutions.

| Property | Description | Typical Applications | Advantages |

|---|---|---|---|

| Thermal Stability | Withstands high temperatures up to 260°C. | Aerospace, automotive components. | Helps maintain dimensional stability under heat. |

| Chemical Resistance | Resistant to a wide range of chemicals. | Chemical processing equipment. | Long-lasting performance in harsh environments. |

| Electrical Insulation | Excellent dielectric properties for electrical applications. | Electrical connectors, insulators. | Prevents electrical leakage and enhances safety. |

| Mechanical Strength | Strong and durable material with high tensile strength. | Structural components in high-stress environments. | Reduced need for frequent replacements. |

| Weight | Lightweight compared to metals, yet strong. | Automotive lightweighting applications. | Improves fuel efficiency by reducing overall weight. |

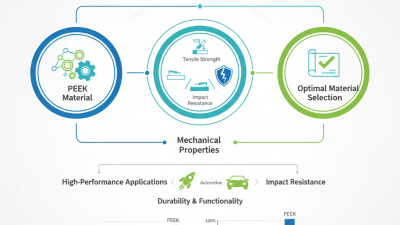

Polyetheretherketone (PEEK) has rapidly gained recognition in the engineering sector due to its excellent mechanical and thermal properties. Known for its outstanding resistance to chemicals, this high-performance polymer is particularly beneficial in applications that require durability and stability under extreme conditions. According to industry reports, the global PEEK market is projected to grow significantly, driven by increasing demand in aerospace, medical, and automotive sectors. The material's ability to maintain properties across a wide temperature range—typically between -50°C to 260°C—makes it ideal for applications that experience fluctuations in heat and harsh environments.

One of the notable benefits of using PEEK in engineering applications is its high strength-to-weight ratio. Unlike traditional materials such as metals, PEEK is lightweight yet robust, which can lead to improved energy efficiency and reduced fuel consumption in aerospace designs. Additionally, its low friction properties and wear resistance make PEEK an excellent choice for components such as bearings and seals. A study by the International Journal of Engineering Materials and Structures highlights that components manufactured from PEEK can reduce wear rates by nearly 40% when compared to other materials, offering substantial cost savings and prolonged service life.

The biocompatibility of PEEK further extends its appeal, particularly in the medical field. Its inert nature allows for safe implantation in the human body, which is confirmed by data from various clinical trials indicating positive patient outcomes. The versatility of PEEK makes it a preferred material in the manufacturing of medical devices, orthopedic implants, and dental components. As the industries seek to innovate and enhance the performance of their products, the incorporation of PEEK into engineering designs continues to rise, reflecting its remarkable benefits in improving efficiency and safety.

Processing and fabricating Peek Polyetheretherketone (PEEK) requires a thorough understanding of its unique properties. One key best practice is to optimize the temperature settings during machining operations. PEEK has a high melting point and is resistant to thermal degradation, but excessive heat can still damage its structure. Maintaining a steady machining temperature below the material’s decomposition threshold, around 400°C, ensures that the integrity of the polymer is preserved while achieving smooth finishes and precise dimensions.

Another critical aspect is the choice of tools and cutting techniques. Employing sharp cutting tools made from carbide materials can reduce the friction and heat generated during the cutting process. It's also advisable to use coolant or lubrication during machining to enhance tool life and improve the surface finish of the workpiece. Additionally, slow feed rates can be effective in preventing unwanted thermal buildup, minimizing the risk of warping or changes in dimensional stability. Implementing these best practices will maximize the performance and durability of PEEK components in demanding applications.

Polyetheretherketone (PEEK) is a high-performance thermoplastic renowned for its exceptional mechanical properties and resistance to chemicals, heat, and radiation. Its unique attributes make it an ideal material in various industries, including aerospace, automotive, and medical fields. In aerospace, PEEK is utilized in components such as cable insulation, brackets, and other parts that require durability and lightweight characteristics. The material's ability to withstand extreme temperatures and its low flammability often meets stringent safety standards critical to aerospace applications.

In the automotive sector, PEEK plays a crucial role due to its excellent wear resistance and dimensional stability. It is frequently used in manufacturing high-performance seals, bearings, and other components that contribute to a vehicle's efficiency and longevity. The material not only supports lightweight designs, which enhance fuel economy but also offers an increase in overall reliability under harsh operating conditions.

The medical industry extensively applies PEEK to create implants and surgical instruments. Its biocompatibility and sterilization capabilities make it suitable for long-term use within the human body. Additionally, PEEK's versatility allows for customization in various medical applications, leading to improved patient outcomes. As industries continue to seek advanced materials with superior performance characteristics, PEEK remains at the forefront, driving innovation and efficiency across diverse applications.

The future of polyetheretherketone (PEEK) material development is poised for exciting advancements as industries increasingly recognize its unique properties and versatility. As manufacturers strive for enhanced performance in extreme conditions, ongoing research is focused on improving PEEK’s thermal stability, chemical resistance, and mechanical strength. The trend towards lightweight materials in aerospace, automotive, and medical applications has further fueled the innovation of PEEK composites that integrate new additives or blend it with other polymers to achieve even higher performance metrics.

In addition to traditional applications, the exploration of PEEK in additive manufacturing is gaining momentum. 3D printing technologies are being developed to allow for the production of complex geometries that were previously unattainable. This evolution not only helps reduce waste but also enables custom solutions tailored to specific project requirements. As environmentally conscious practices shape the future of material science, the recyclability of PEEK is also being researched, potentially leading to a more sustainable lifecycle for this robust polymer. With these trends, PEEK is set to maintain its pivotal role in advancing materials engineering in various high-tech applications.