The density of PEEK material is a critical factor in various industries. PEEK, or Polyether ether ketone, is known for its exceptional thermal and chemical resistance. According to a report by the Polymer Science Society, the typical density of PEEK materials ranges between 1.30 to 1.45 g/cm³. This range makes it ideal for applications that require strength and lightness, such as aerospace and automotive sectors.

Dr. Emily Hartman, a leading expert in high-performance polymers, once stated, "Understanding the density of PEEK material is crucial for engineers designing parts that withstand extreme conditions." This insight highlights the importance of density in ensuring the performance of PEEK components.

However, the density of PEEK material is not just a number. It affects processing methods, mechanical properties, and end-use applications. There are still concerns in optimizing density without compromising functionality. Industries must continuously explore the trade-offs involved in this balancing act. As we delve deeper into this topic, the implications of density on material performance come to the forefront.

PEEK, or polyether ether ketone, is a high-performance thermoplastic known for its impressive thermal and mechanical properties. Its density is a key factor in various applications, influencing strength and durability. Typically, PEEK has a density of around 1.30 g/cm³, making it lightweight compared to metals while still providing high strength. This balance allows it to be a preferred material in aerospace, automotive, and medical industries.

Despite its many advantages, the density of PEEK can sometimes be a double-edged sword. While a lighter material can enhance performance, it may also lead to concerns about structural integrity in certain high-stress applications. Some users may find it challenging to balance weight with strength, especially in designs requiring both. It's essential to evaluate these factors carefully during the material selection process. In practice, it often takes trial and error to achieve the right balance, leading to deeper insights about PEEK's capabilities. Understanding these nuances can help engineers optimize their designs effectively.

PEEK, or Polyether Ether Ketone, is a high-performance thermoplastic. It offers remarkable properties like strength, chemical resistance, and thermal stability. Its density typically ranges from 1.30 to 1.45 g/cm³. These properties make it a choice material in various high-stress applications.

When considering PEEK, its temperature resistance is compelling. It can withstand continuous temperatures up to 260 degrees Celsius. This makes it suitable for industries like aerospace and medical. Users often note that its toughness surpasses many other plastics. However, it is essential to remember that PEEK can be challenging to process. Its high melting point can complicate traditional manufacturing techniques.

**Tips:** When working with PEEK, invest time in understanding its mechanical properties. This knowledge will help you choose appropriate applications. Additionally, always consider the processing requirements before starting a project. A detailed plan can prevent unnecessary challenges.

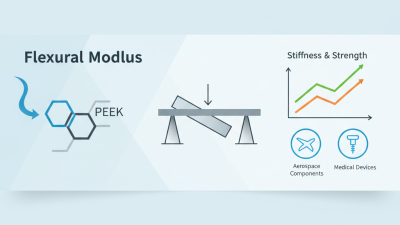

| Property | Value | Unit |

|---|---|---|

| Density | 1.30 - 1.45 | g/cm³ |

| Tensile Strength | 90 - 100 | MPa |

| Compressive Strength | 200 - 250 | MPa |

| Flexural Modulus | 4000 - 5000 | MPa |

| Melting Point | 343 | °C |

| Thermal Conductivity | 0.25 | W/(m·K) |

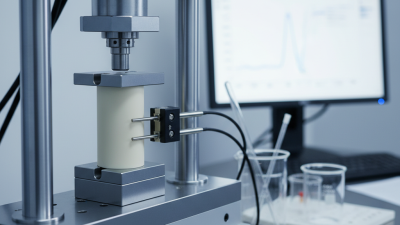

The density of PEEK, or polyether ether ketone, is influenced by several factors. One of the primary factors is the molecular weight of the polymer. Higher molecular weight often leads to increased density. According to industry reports, standard PEEK density ranges from 1.30 g/cm³ to 1.45 g/cm³, depending on the manufacturing processes used.

Another significant factor is the processing conditions. The temperatures and pressures applied during injection molding or extrusion can alter the material’s final density. Higher processing temperatures often result in a more compacted structure. Additionally, additives used during production can affect the overall density. For example, fillers like carbon black or glass fibers can increase density, but they might also impact other properties such as flexibility or thermal resistance.

Moisture content also plays a role in density variations. PEEK can absorb moisture, which may lead to a temporary increase in weight without a change in volume. This is a consideration for applications in humid environments where accuracy in density is crucial. Understanding these factors helps in predicting PEEK's performance in various applications and ensures proper selection for specific engineering needs.

The density of PEEK (Polyether ether ketone) material can vary based on several factors including the manufacturing process and any additives used. This chart illustrates the average density of PEEK material across different conditions, demonstrating how density can fluctuate based on specific properties.

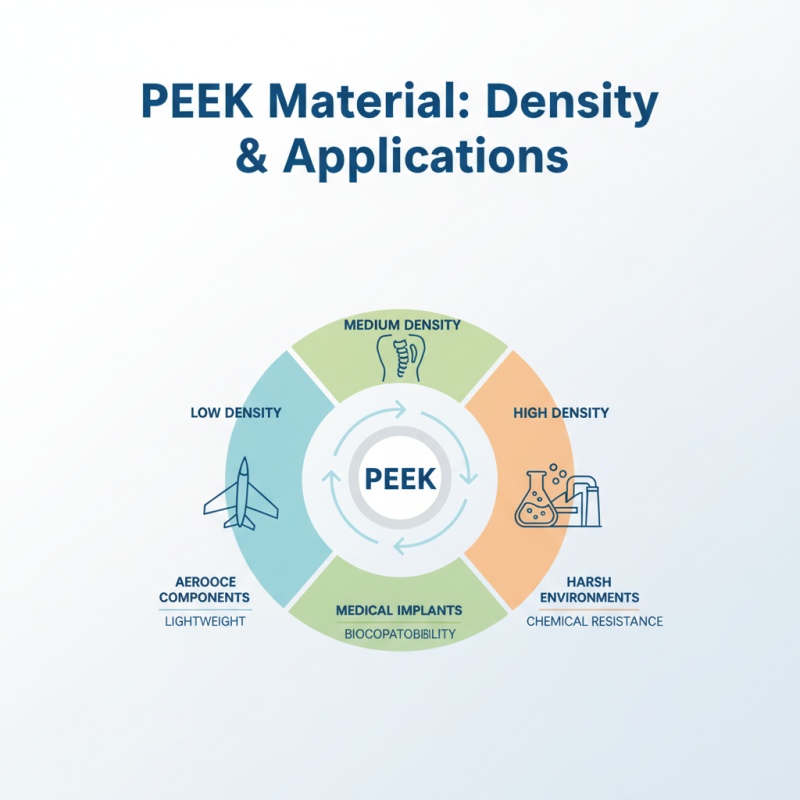

PEEK material, known for its high performance, finds varied applications based on its density. Its lightweight nature makes it suitable for aerospace components. In the medical field, PEEK is used for implants due to its biocompatibility. The material's density also contributes to its chemical resistance, allowing it to thrive in harsh environments.

For automotive parts, PEEK’s unique properties offer weight savings without sacrificing strength. This is crucial for improving fuel efficiency. However, the density can sometimes present challenges in manufacturing processes. Customizing the material to specific applications may require precise adjustments.

Tips: Always consider the end-use environment when selecting PEEK for projects. Testing material properties under actual conditions can reveal surprising results. Moreover, collaborating with materials experts saves time and resources on design efforts.

PEEK, or polyether ether ketone, is a high-performance polymer known for its exceptional properties. Its density typically ranges from 1.3 to 1.5 g/cm³. Compared to other polymers, PEEK has a higher density, which contributes to its strength and durability. For instance, polyethylene, which has a density around 0.9 g/cm³, is significantly lighter but not as robust. This difference makes PEEK a favored choice in demanding applications.

In a comparative analysis, PEEK outshines many common polymers like polypropylene and polystyrene. These materials usually have lower densities and cannot withstand the same temperatures. However, this higher density in PEEK also poses challenges, such as increased weight in applications where lightweight materials are crucial. Engineers often have to balance the benefits of strength against potential downsides like weight.

When considering alternatives, it’s essential to think about the specific requirements of an application. Sometimes, a lighter polymer might suffice if it meets strength needs. Reflecting on PEEK's density reveals a trade-off that requires careful consideration. Understanding these nuances helps in selecting the right material for each unique project.