Understanding the compressive strength of PEEK (Polyether Ether Ketone) is essential for various applications in engineering and manufacturing. This high-performance polymer boasts unique properties, making it suitable for demanding environments. The compressive strength of PEEK plays a crucial role in its performance, especially in aerospace and medical devices.

Notably, PEEK can withstand high pressures and temperatures. Its impressive compressive strength means it can maintain structural integrity under heavy loads. However, the material’s performance varies based on factors like temperature and humidity. There are nuances that require evaluation and understanding.

Despite its strength, PEEK isn't perfect. It can be expensive and may not be the best choice for every application. Knowing the limits and advantages of the compressive strength of PEEK is important for informed decision-making. This exploration will highlight ten critical facts about PEEK, deepening your knowledge and understanding of this remarkable material.

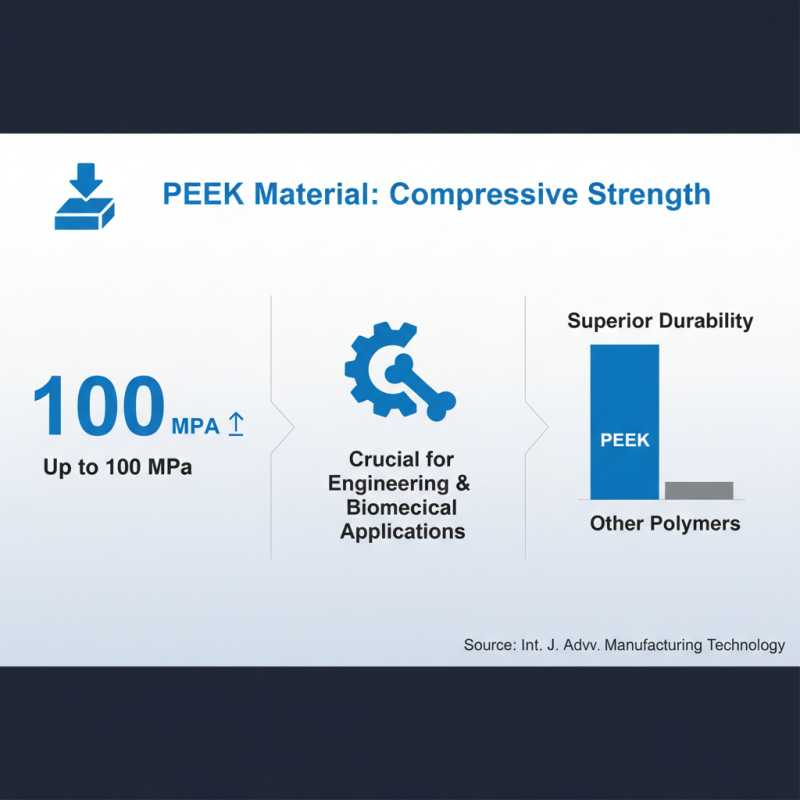

Compressive strength refers to a material's ability to withstand axial loads without failing. For PEEK (polyetheretherketone) materials, this characteristic is crucial in various applications, particularly in engineering and biomedical fields. According to a report by the International Journal of Advanced Manufacturing Technology, PEEK exhibits compressive strength values reaching up to 100 MPa. Such figures highlight its impressive durability compared to many other polymers.

The importance of PEEK's compressive strength cannot be overstated. In aerospace, it plays a vital role in lightweight parts that endure high stress. In medical devices, it ensures long-term stability and performance. Industry studies reveal that PEEK components can operate safely in extreme environments, maintaining structural integrity.

Tips: Always consider the specific application when selecting materials. Not every PEEK grade is suitable for high-stress conditions. Additionally, while PEEK shows remarkable performance, it can be brittle under certain circumstances. Testing is essential to ensure reliability. Scrutinizing data from credible research can guide decisions effectively.

The compressive strength of PEEK (Polyether ether ketone) is influenced by several key factors. One major element is the material's crystallinity. Higher crystallinity often leads to improved mechanical properties. Crystallinity levels can vary significantly based on processing methods. For instance, studies show that a crystallinity of around 60% can enhance compressive strength by up to 30% when compared to lower crystallinity levels.

Another important factor is temperature. PEEK exhibits a notable drop in compressive strength at elevated temperatures. Above 200°C, the polymer’s ability to bear weight diminishes. According to research, the compressive strength can fall by 50% when temperatures exceed this threshold. Thus, applications in high-heat environments must consider this aspect carefully.

Additionally, the processing conditions used to fabricate PEEK materials play a crucial role. Injection molding yields different compressive strengths compared to machining processes. This variation can be attributed to the orientation of the molecular chains. Moreover, inconsistent sample preparation can lead to variations in test results. A thorough understanding of these factors is essential for those looking to capitalize on PEEK's robust properties in practical applications.

When comparing the compressive strength of PEEK to other polymers, the contrast is striking. PEEK has a compressive strength that significantly outperforms many standard polymers. Its resistance to deformation under pressure is notable, making it suitable for demanding applications. Many common polymers, like polyethylene or polystyrene, exhibit lower compressive strength. They often fail under stress, which limits their use in critical environments.

However, it's essential to recognize that PEEK's strengths come with challenges. While its performance is impressive, processing PEEK can be complex. Many manufacturers may find the costs and techniques involved to be a barrier. Other polymers may be easier to mold and shape. There’s also the factor of weight; PEEK is lightweight yet strong, unlike some metal composites. But, the learning curve for using PEEK effectively can be steep.

In specific applications, one might find alternatives that are more cost-effective, even if they compromise on compressive strength. For instance, using nylon in non-critical areas can save resources. Thus, it's valuable to weigh the benefits against the limitations of different materials. Understanding these nuances is crucial in material selection.

| Property | PEEK Value | Polymer Comparison | Comparative Value |

|---|---|---|---|

| Compressive Strength | 100 MPa | PTFE | 25 MPa |

| Compressive Modulus | 4.0 GPa | Nylon | 2.5 GPa |

| Tensile Strength | 75 MPa | PVC | 50 MPa |

| Impact Strength | 23 kJ/m² | Polycarbonate | 17 kJ/m² |

| Thermal Conductivity | 0.25 W/m·K | ABS | 0.15 W/m·K |

| Heat Deflection Temp | 150 °C | Polystyrene | 70 °C |

| Chemical Resistance | Excellent | Polypropylene | Good |

| Biocompatibility | High | Polystyrene | Moderate |

| Density | 1.30 g/cm³ | Polyethylene | 0.92 g/cm³ |

| Weather Resistance | High | Polyester | Moderate |

PEEK, or polyether ether ketone, is known for its impressive compressive strength. This property makes it ideal for numerous industrial applications. In the aerospace sector, PEEK is used in structural components due to its ability to withstand high stress. It can endure extreme temperatures and harsh conditions without losing functionality.

Additionally, PEEK finds significant use in the medical field. Its biocompatibility is a huge advantage. Surgeons prefer it for implants that require durability and strength. Using materials that can handle compression in critical applications is essential for patient safety. However, the cost of PEEK can be prohibitive, leading some manufacturers to seek alternatives.

There are challenges as well. The processing of PEEK can be complex. It requires precise conditions to achieve optimal strength. In some cases, engineers might overlook these factors, leading to failures. Such mistakes can be costly in terms of both time and resources. Understanding the compressive strength of PEEK is crucial but so is recognizing the potential pitfalls in its application.

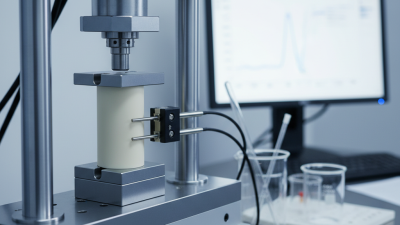

Compressive strength is a critical property of PEEK (polyether ether ketone). It indicates how well the material can withstand compressive forces. Testing methods vary, but some are more reliable than others.

One common method is the ASTM D695 standard. This involves preparing cylindrical PEEK samples. After curing, they undergo compression until failure. Data shows that PEEK boasts a compressive strength between 80-150 MPa. Some reports indicate higher values in controlled environments.

Another method involves dynamic mechanical analysis (DMA). This technique provides insights into the viscoelastic properties of PEEK. It helps determine how the material behaves under varying temperatures and rates of loading. Some tests reveal inconsistencies in results due to sample preparation issues. Flaws in molding or surface imperfections can lead to misleading strength data. Adjusting testing parameters might yield varied insights, but standardization remains a challenge.