The demand for superior performance in engineering is rising. Companies seek materials that combine strength, durability, and heat resistance. PEEK (polyether ether ketone) material stands out in this landscape. According to a recent market analysis, the global PEEK market is projected to reach $1.24 billion by 2025, showcasing rapid growth driven by aerospace and automotive sectors.

PEEK materials exhibit exceptional mechanical properties and resistance to chemicals. For example, they remain stable at temperatures exceeding 250°C. This capability makes PEEK essential in high-performance applications such as medical devices and electrical insulators. However, while PEEK's advantages are clear, challenges remain. High costs and processing complexities can limit its widespread adoption. Engineers must weigh these factors when considering PEEK for their projects.

Innovations in PEEK material continue to evolve. New formulations improve its properties, making it even more versatile. Yet, exploring these advancements is vital for advancing engineering solutions. Understanding PEEK fully aids engineers in making informed choices, shaping the future of the industry.

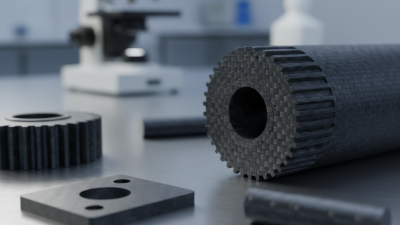

PEEK (Polyether Ether Ketone) materials have gained popularity in engineering applications due to their exceptional properties. They are lightweight, strong, and resistant to high temperatures. These characteristics make them suitable for various industries, including aerospace and automotive. PEEK can withstand extreme conditions, which is vital in critical engineering settings. Its strength-to-weight ratio is impressive, making it an ideal choice for designing robust components.

However, working with PEEK requires careful considerations. The manufacturing process can be complex, and achieving precise specifications can be challenging. Engineers must consider factors like machining and surface finishes to optimize performance. PEEK's higher cost compared to other polymers can be a barrier. Yet, when the application demands durability and reliability, PEEK often proves cost-effective over time.

As applications grow more demanding, innovations in PEEK materials continue to emerge. Enhanced composites and blends offer improved performance metrics. There is still room for exploration and improvement in recycling and sustainability. Balancing the benefits of PEEK with its challenges remains an ongoing reflection for engineers. Such considerations ensure that advances in PEEK materials lead to superior performance while addressing environmental concerns.

Peek materials are renowned for their exceptional properties that significantly enhance performance in engineering applications. One key property is their high thermal stability. They can withstand temperatures up to 260°C without losing integrity. This makes them ideal for environments where heat resistance is crucial.

Another important characteristic of Peek is its chemical resistance. It remains stable even when exposed to harsh chemicals. Engineers often find this invaluable in sectors like aerospace and automotive. However, the challenge lies in processing these materials. The difficulty in machining peek can lead to waste if not handled correctly.

Additionally, the low coefficient of friction in peek enhances wear resistance. This reduces the need for frequent replacements, saving costs in the long run. Despite their advantages, the cost of peek materials can be a barrier for some projects. Often, it's essential to evaluate if the performance benefits justify the investment. Balancing performance with cost is an ongoing conversation in engineering circles.

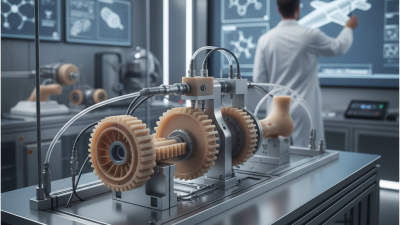

Recent innovations in PEEK material technology have dramatically transformed engineering applications. PEEK, or polyetheretherketone, is renowned for its high-performance capabilities. New formulations are enhancing its resistance to wear and high temperatures. Advanced processing methods are also emerging, allowing for greater design flexibility and molding precision.

Research indicates that the demand for PEEK materials in aerospace and medical industries is growing rapidly. A recent report highlights a projected annual growth rate of over 10% in the PEEK market. Improved mechanical properties ensure that PEEK components can withstand extreme conditions. This makes them ideal for critical applications where failure is not an option.

Tips: When selecting PEEK for your projects, consider the operational environment. Analyze temperature extremes and mechanical stresses that your components may face. Upper-grade PEEK can resist 250 °C without losing integrity; however, careful evaluation is essential. Also, watch for potential brittleness in certain formulations. Adjust your designs accordingly to mitigate these risks.

Polyether ether ketone (PEEK) is a versatile thermoplastic known for its exceptional strength and durability. Its applications span various engineering fields, showcasing its adaptability. In aerospace, PEEK is prized for its lightweight properties, contributing to fuel efficiency. Components withstand harsh environments without compromising performance. Using PEEK in this sector offers both reliability and longevity.

In the medical field, PEEK provides biocompatibility and high-temperature resistance. Surgeons use PEEK for implants, because its non-reactive properties are crucial. This material allows for innovations in orthopedic devices. However, challenges remain, such as its high cost compared to traditional alternatives. Engineers must balance cost and performance carefully.

PEEK is also making waves in electronics, where heat resistance is vital. Insulating components made of PEEK protect against extreme temperatures. This improves device longevity and reliability. Despite its advantages, engineers must consider its processing difficulties. An ideal formulation is essential to avoid production flaws. This ongoing exploration continues to drive innovations in engineering.

| Innovation | Application Field | Key Benefits | Performance Metrics |

|---|---|---|---|

| High-Temperature Resistance PEEK | Aerospace | Withstands extreme temperatures | Continuous use at 250°C |

| Carbon-Filled PEEK | Mechanical Engineering | Improved wear resistance | Reduced friction coefficient |

| Glass-Filled PEEK | Automotive | Enhanced strength and stiffness | Increased tensile strength by up to 50% |

| PEEK Composites | Medical Devices | Biocompatibility | Suitable for long-term implants |

| Low Friction PEEK | Energy Sector | Reduced wear and energy consumption | Up to 30% lower friction |

| Flame Retardant PEEK | Electronics | Improved safety | UL 94 V-0 rating |

| Conductive PEEK | Semiconductor | Electrostatic discharge protection | Surface resistivity of 10^6 Ohms |

| Radiolucent PEEK | Radiology | Ideal for imaging applications | Minimized artifacts in scans |

| Low-Weight PEEK | Transportation | Reduces overall vehicle weight | Weight reduction of up to 40% |

| PEEK for 3D Printing | Additive Manufacturing | Custom part production | High dimensional accuracy |

The future of PEEK material development shows exciting trends that could reshape engineering. Advances are pushing the boundaries of performance. Lightweight yet sturdy options are emerging. These innovations focus on improving thermal stability and resistance to chemicals. Enhanced fabrication techniques allow for unique designs that were not feasible before. This evolution prompts engineers to rethink traditional applications.

There is an emphasis on bio-based PEEK materials. Sustainability is becoming a priority. Industries are exploring eco-friendly alternatives. However, not all innovative attempts succeed as planned. The challenge lies in balancing performance with environmental impact. Engineers often find themselves navigating a complex landscape of options. Testing and refinement remain essential in this ongoing journey.

Furthermore, the integration of smart technology into PEEK composites is gaining attention. Imagine materials that can self-diagnose damage over time. This concept is still in the early stages, but the potential is vast. The quest for functional biomimetic applications invites scrutiny. How close are we to achieving this? Addressing these questions will shape future exploration in PEEK materials.