The demand for lightweight and high-performance materials is on the rise. In industries like aerospace and automotive, the importance of "peek material composition" cannot be overstated. According to a recent report by Global Market Insights, the PEEK market is projected to exceed $2 billion by 2026. This surge indicates a significant shift in material preferences, driven largely by their superior mechanical properties and thermal stability.

Dr. Emily Carter, a noted expert in advanced materials, emphasizes the advancements in peek material composition. She stated, “Understanding the specifics of peek material composition is pivotal for optimizing applications.” Her insights highlight how precise formulations can enhance performance metrics in extreme conditions.

Applications are varied, ranging from medical devices to electrical components. Each industry demands unique properties, adjusting the composition accordingly. Challenges persist, as not all formulations yield ideal results. Continuous research is needed to push these materials further, ensuring they meet the evolving needs of modern industries.

In 2026, the composition of PEEK materials holds significant promise for various industrial applications. PEEK, or polyether ether ketone, is known for its durability and high-performance characteristics. The base polymer consists of a unique blend of ether and ketone groups, allowing it to withstand harsh environments. This year, manufacturers are exploring innovative additives to enhance PEEK's mechanical strength and thermal stability.

Reinforcements such as carbon fibers and glass fibers are increasingly integrated into the base composition. This blend allows PEEK to achieve remarkable stiffness while maintaining a lightweight profile. Some applications include aerospace components and medical devices requiring sterilization. However, the cost of production remains a concern. Balancing performance with affordability is a challenge many faces in the industry.

The market continues to evolve, with potential for bio-based alternatives emerging. These options could provide environmentally friendly solutions. Yet, achieving the same level of performance is a complex task. The focus on sustainability is worth noting. However, manufacturers must ensure that the new compositions do not compromise quality. Navigating this landscape requires continuous research and development.

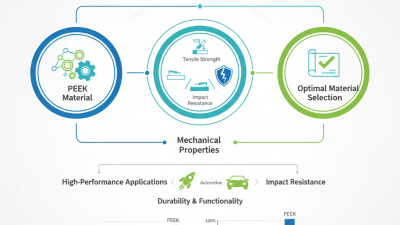

This bar chart illustrates the composition of different types of PEEK materials along with their applications as of 2026. The data showcases the percentage composition of key PEEK variations.

Polyether ether ketone (PEEK) is gaining traction in various industries due to its unique properties. Thermal resistance is one of PEEK's standout features. It can withstand temperatures up to 260°C (500°F) without losing integrity. This makes it ideal for applications in aerospace and automotive sectors, where high-temperature stability is crucial.

Chemically, PEEK is resistant to a wide range of solvents, acids, and bases. This resistance extends its lifecycle in harsh environments, making it valuable in chemical processing applications. Data shows that PEEK maintains its strength and stiffness even after prolonged exposure to various chemicals. These qualities set PEEK apart from other thermoplastics.

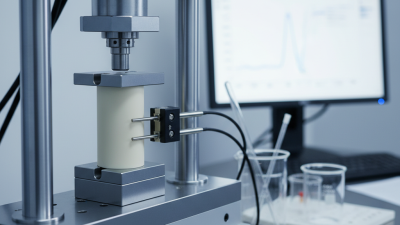

**Tips:** When selecting PEEK for your application, consider thermal load and the chemical environment. A thorough analysis can prevent potential failures. Remember, while PEEK is robust, improper handling can lead to issues. Always assess compatibility with other materials in your design.

Mechanical properties are also noteworthy. PEEK exhibits impressive strength and stiffness, making it suitable for structural components. Reports indicate that PEEK retains its mechanical properties at high temperatures, unlike many alternatives. However, this combined strength does not automatically imply ease of processing, which can be a concern for manufacturers.

**Tip:** Stay informed on the latest processing techniques. This can help streamline your production, ensuring optimal performance.

| Type of PEEK | Thermal Stability (°C) | Chemical Resistance | Tensile Strength (MPa) | Applications |

|---|---|---|---|---|

| Unfilled PEEK | 250 | Excellent | 80 | Aerospace, Automotive |

| Carbon Fiber Reinforced PEEK | 260 | Very Good | 100 | Medical Devices, Industrial Components |

| Glass Fiber Reinforced PEEK | 240 | Good | 90 | Electronics, Oil & Gas |

| High-Performance PEEK | 300 | Outstanding | 120 | Space Exploration, High-Temperature Applications |

| Conductive PEEK | 250 | Good | 85 | Electromagnetic Interference Shielding |

Peek (Polyether ether ketone) has emerged as a crucial material in both aerospace and automotive sectors. Its ability to withstand high temperatures and resist wear makes it ideal for demanding applications. In aerospace, Peek is used in components such as insulators and structural parts. These components can endure extreme conditions while maintaining structural integrity. The lightweight nature of Peek helps improve fuel efficiency, an important consideration in modern aerospace engineering.

In the automotive industry, Peek is used in engine components and connectors. Its chemical resistance ensures longevity and reliability in harsh environments. The use of Peek can lead to lighter vehicles, reducing overall energy consumption. This is vital as manufacturers strive for sustainability.

**Tips:** When selecting materials, consider weight and durability. Heavy materials can decrease efficiency. Experiment with different compositions to find optimal performance. Always test prototypes under real conditions to identify potential weaknesses. Small changes can lead to significant improvements in application effectiveness. Balancing cost and quality during material selection is crucial.

The demand for PEEK resin is steadily increasing. This high-performance thermoplastic is becoming essential in various industries. Industries like aerospace, automotive, and medical are driving this trend. High temperatures and harsh conditions require materials that perform reliably. PEEK meets these demands with exceptional strength and durability.

Supply dynamics are shifting too. Manufacturers are investing in expanding production capabilities. However, sourcing raw materials for PEEK can be challenging. The fluctuating availability of specific chemicals is a concern. Quality control remains essential in ensuring consistent product performance. Companies must adapt to these changes to maintain their competitive edge.

Market trends indicate a growing focus on sustainability. Many companies seek eco-friendly alternatives to conventional materials. This shift may require significant adjustments in production methods. Development of biodegradable PEEK could be a game changer. Yet, balancing performance with sustainability poses challenges. There is much room for exploration in this field.

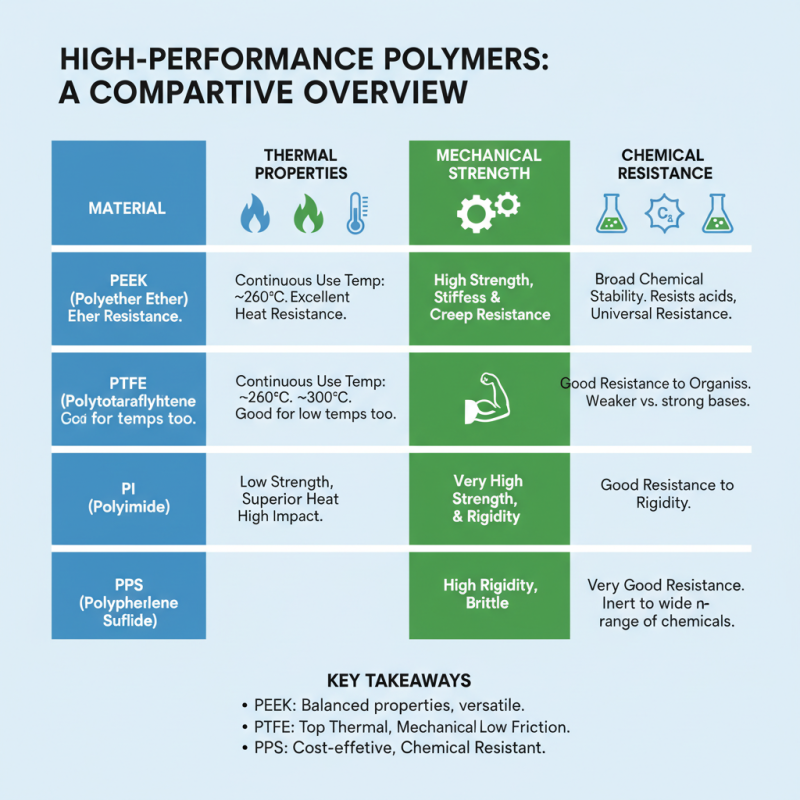

Peek, or polyether ether ketone, is known for its outstanding thermal and mechanical properties. However, it's essential to compare it with other high-performance polymers. Materials like PEEK often excel in heat resistance and chemical stability. Yet, some alternatives can match or even exceed its performance in specific applications.

For example, polyphenylene sulfide (PPS) displays excellent chemical resistance. In some environments, it may outperform PEEK. According to industry reports, PPS can maintain its integrity at temperatures up to 260°C, while PEEK generally maxes out around 250°C. This minor difference might influence material choice in high-demand sectors.

**Tip:** When evaluating materials, assess the specific operating environment and required characteristics.

Another alternative, polyimide (PI), showcases impressive electrical insulation properties. It can operate effectively in extreme temperatures, making it a favorite for aerospace applications. However, PI often lacks the toughness of PEEK, making it less suitable where impact resistance is crucial.

**Tip:** Be mindful of trade-offs. Understand that while one polymer may excel in one area, it may not perform as well in another.

In summary, while PEEK is a leader in high-performance polymers, alternatives like PPS and PI are worth considering. Each material possesses unique strengths, underscoring the importance of context in material selection.