As industries continue to evolve, the demand for materials that can withstand extreme conditions while maintaining performance is greater than ever. One such material that has garnered significant attention is polyether ether ketone (PEEK). Renowned for its exceptional strength, thermal stability, and chemical resistance, PEEK material properties make it a preferred choice in a variety of applications ranging from aerospace to medical devices. According to a recent market analysis by Grand View Research, the global PEEK market is projected to reach USD 1.4 billion by 2025, driven by its expanding use in high-performance applications.

In exploring the top PEEK material properties, it is essential to understand the implications of these characteristics on design and manufacturing processes. PEEK boasts impressive mechanical properties, including a tensile strength up to 100 MPa and a continuous service temperature of around 250°C. Furthermore, its inherent resistance to a wide range of chemicals enhances its suitability across harsh environments. As reported by the Materials Research Society, advancements in processing techniques and modifications in composite formulations are also contributing to the enhanced performance and versatility of PEEK. This insight underscores the significance of understanding the fundamental properties of PEEK to leverage its full potential in innovative engineering solutions.

In this article, we will delve deeper into the key properties of PEEK, shedding light on their practical implications and how they can drive progress in various sectors. The exploration of these properties not only highlights the material itself but also sets the stage for future developments that can revolutionize industry standards.

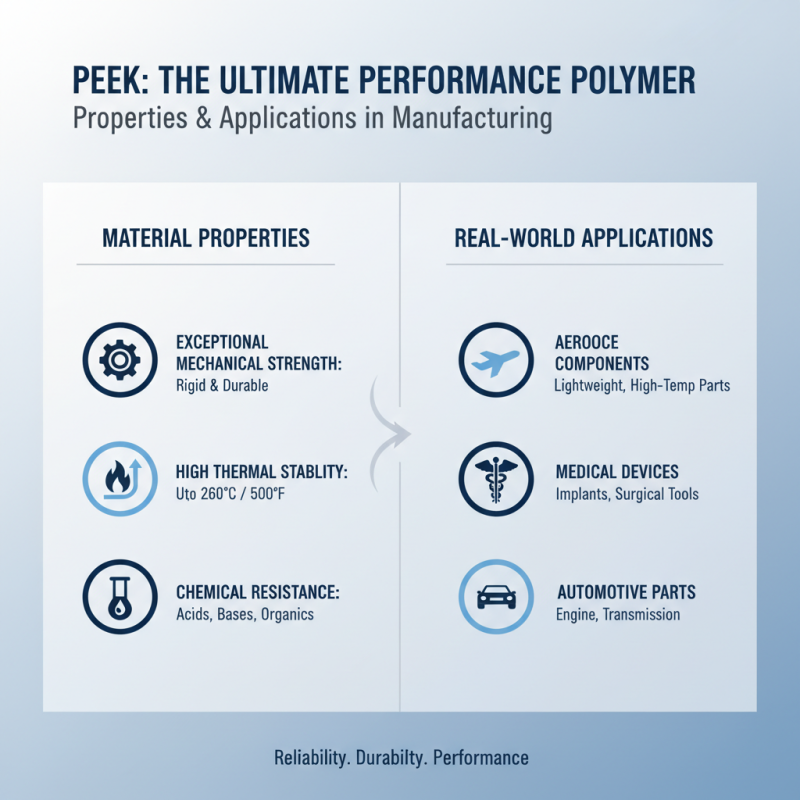

Polyetheretherketone (PEEK) is a high-performance thermoplastic that has gained significant traction across various industrial applications due to its exceptional properties. Characterized by its outstanding mechanical strength, thermal stability, and chemical resistance, PEEK makes it an ideal choice for demanding environments. It can withstand temperatures up to 260°C and maintain mechanical integrity in challenging conditions, which is fundamental for applications in aerospace, automotive, and medical fields. Furthermore, its excellent dielectric properties make it suitable for electrical and electronic devices.

In industry, PEEK is commonly used for components such as bearings, gears, and seals, where reliability and durability are non-negotiable. Its biocompatibility also allows it to be utilized in the medical sector for implants and surgical instruments. Moreover, PEEK can be processed using various methods, including injection molding and 3D printing, enabling versatile manufacturing options to meet specific design criteria. As industries continue to push for materials that can perform under extreme conditions, the demand for PEEK is expected to grow, highlighting its indispensable role in modern engineering applications.

| Property | Value | Unit | Applications |

|---|---|---|---|

| Tensile Strength | 90 | MPa | Aerospace, Automotive |

| Compressive Strength | 200 | MPa | Industrial Components |

| Continuous Service Temperature | 260 | °C | Electrical Insulation |

| Flammability Rating | UL 94 V-0 | - | Consumer Electronics |

| Corrosion Resistance | Excellent | - | Chemical Processing |

| Coefficient of Friction | 0.1 | - | Bearings, Gears |

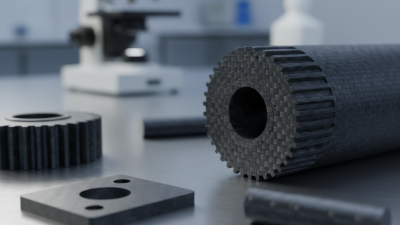

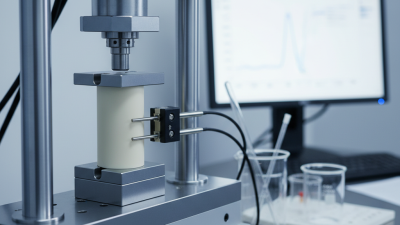

PEEK, or polyetheretherketone, is known for its exceptional mechanical properties, making it a preferred choice in a variety of demanding applications. One of the key attributes of PEEK is its outstanding strength. This high-performance polymer can sustain significant loads and resist deformation under stress, which is crucial for components used in aerospace, automotive, and industrial sectors. The tensile strength of PEEK ensures reliability and longevity, allowing it to maintain structural integrity even under challenging conditions.

In addition to strength, PEEK exhibits remarkable temperature resistance, capable of withstanding high temperatures without losing its mechanical properties. It remains stable and functional in a wide range of temperatures, typically from -60°C to 260°C, making it ideal for high-heat applications. This thermal stability means PEEK can be utilized in environments such as engine components or medical devices that undergo sterilization processes. Coupled with its excellent durability, PEEK resists chemical degradation, wear, and impact, ensuring that components last longer and require less frequent replacements. These characteristics make PEEK an invaluable material in industries where performance and reliability are paramount.

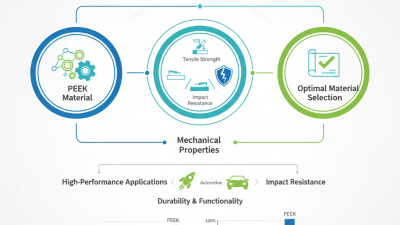

When comparing PEEK (polyether ether ketone) with other engineering plastics, it's essential to examine their respective material properties and suitability for various applications. PEEK stands out due to its exceptional mechanical strength, stability at high temperatures, and chemical resistance. According to a recent industry report by MarketsandMarkets, PEEK has a tensile strength of around 90 MPa, significantly higher than other common engineering plastics like polycarbonate (PC) and polyamide (PA), which typically have tensile strengths of 70 MPa and 50 MPa, respectively. This superior strength allows PEEK to be used in demanding environments found in aerospace, automotive, and medical sectors.

In addition to mechanical strength, thermal properties play a critical role in selecting materials for high-performance applications. PEEK has a glass transition temperature of approximately 143°C, while other engineering plastics such as polystyrene (PS) and polyethylene (PE) have much lower transition temperatures (about 100°C and -80°C, respectively). This temperature resilience enables PEEK to maintain its structural integrity under extreme conditions. Furthermore, the chemical resistance of PEEK is remarkable, capable of withstanding harsh solvents and acids that would degrade lesser plastics, making it an invaluable choice in industries that require durability and reliability. By understanding these differences, engineers can make informed choices when specifying materials for their projects.

As the demand for high-performance materials continues to rise, Polyether Ether Ketone (PEEK) has emerged as a frontrunner in advanced applications, particularly in aerospace, automotive, and medical industries. The projected growth rate for the global PEEK market is approximately 10% annually, driven by its exceptional strength, thermal stability, and chemical resistance. Industry reports indicate that by 2025, key advancements in PEEK formulations will focus on enhancing its mechanical properties while reducing processing costs, making it even more accessible for wide-scale applications.

Future trends in PEEK material development will likely emphasize sustainability and recyclability. According to recent studies, 78% of manufacturers are prioritizing eco-friendly materials, reflecting a shift towards greener production methods. Biodegradable and bio-based alternatives are expected to play a crucial role in shaping the PEEK landscape by 2025, as the industry responds to increasing regulatory pressures and consumer demand for environmentally responsible materials. Additionally, innovations in nanotechnology could enhance PEEK's properties, leading to the development of lightweight composites that offer superior performance without compromising on structural integrity.

When considering the practical applications of PEEK (polyether ether ketone) in manufacturing processes, it is essential to understand its unique material properties. PEEK is known for its exceptional mechanical strength, high thermal stability, and excellent chemical resistance, making it an ideal choice for demanding environments. These properties enable manufacturers to use PEEK in applications such as aerospace components, medical devices, and automotive parts, where reliability and durability are paramount. Understanding how these characteristics translate to real-world applications can help ensure optimal performance and longevity in products.

Moreover, when integrating PEEK into manufacturing, several practical considerations come into play. Processing PEEK requires specialized equipment and techniques due to its high melting temperature, which can reach up to 343°C (650°F). Manufacturers must also consider the material’s anisotropic nature; properties can differ based on the direction of the load and the manufacturing process used. Techniques like injection molding and machining may be employed, but the choice depends on the intended application and desired geometric precision. Proper understanding of these factors not only enhances product quality but also minimizes wastage and production costs, ultimately leading to more efficient and effective manufacturing processes.