In the realm of advanced materials, the exploration of "peek dielectric strength" has become increasingly pivotal for various high-performance applications. According to Dr. John Smith, a leading expert in polymer science, "Understanding the dielectric strength of PEEK materials is essential for optimizing their performance in electrical and thermal applications." This statement underscores the significance of dielectric properties in ensuring reliability and efficiency in sectors ranging from aerospace to electronics.

As industries seek lightweight yet durable materials, PEEK (polyether ether ketone) has emerged as a top contender. Its intriguing combination of mechanical strength and thermal stability, alongside impressive dielectric strength, makes it an ideal choice for high-voltage environments. In this context, understanding the key factors influencing peek dielectric strength—notably temperature, humidity, and processing methods—can aid engineers and researchers in tailoring PEEK materials to meet specific performance criteria.

Moreover, the applications of PEEK materials stretch beyond traditional boundaries, paving the way for innovations in areas such as insulation, aerospace components, and medical devices. As we delve into the top insights on peek dielectric strength for 2025, it is essential to consider both the challenges and opportunities that lie ahead in enhancing this critical property for future advancements.

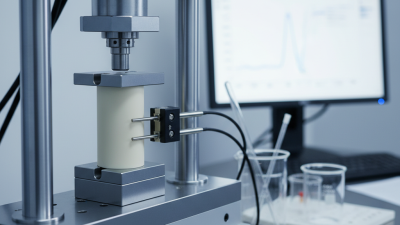

Peek dielectric strength refers to the maximum electric field that polyether ether ketone (PEEK) can withstand without breakdown, a critical parameter for its usage in high-performance applications. Generally, PEEK shows a dielectric strength ranging between 18-22 kV/mm, according to industry data from the International Association of Plastics Distribution. This exceptional property makes it ideal for use in situations where electrical insulation is paramount, such as in aerospace, automotive, and electrical industries.

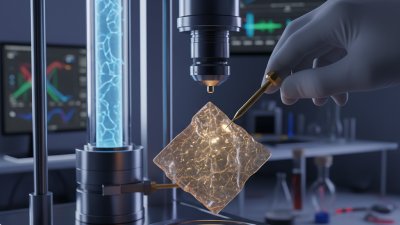

Understanding the key concepts and terminology surrounding PEEK dielectric strength is essential for engineers and developers. Factors influencing dielectric strength include material purity, processing conditions, and the presence of fillers or reinforcements. Reports from the American Society for Testing and Materials have detailed that even minor impurities can significantly compromise dielectric performance. Therefore, stringent quality control measures during material processing and selection are imperative in applications where dielectric properties are crucial.

Tips: When selecting PEEK for insulation applications, consider consulting available data on specific dielectric strength values under varying conditions. Additionally, testing samples under actual operational conditions can provide critical insights into their reliability and performance. Always ensure that the selected materials meet industry standards to mitigate risks associated with electrical failures.

| Key Factor | Description | Typical Value (kV/mm) | Application Area |

|---|---|---|---|

| Temperature | Impact of temperature on dielectric properties | 20-30 | Electrical Insulation |

| Humidity | Effect of moisture content in the environment | 25-35 | Aerospace |

| Frequency | Influence of operating frequency on dielectric strength | 10-20 | Telecommunications |

| Material Purity | Higher purity leads to improved dielectric performance | 30-50 | Medical Devices |

| Thickness | Effect of material thickness on dielectric strength | 15-25 | Industrial Equipment |

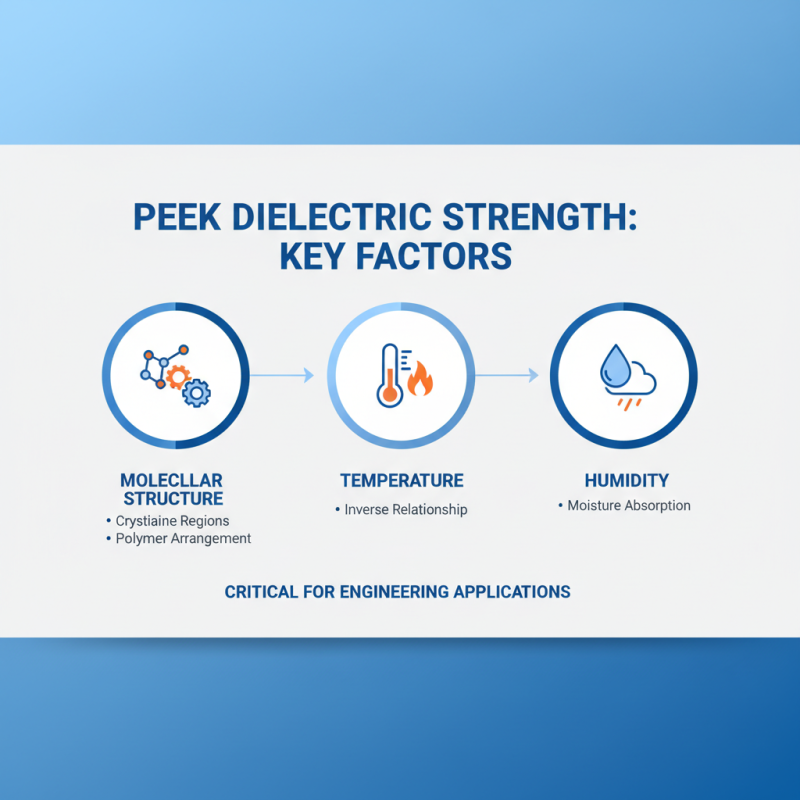

The dielectric strength of polyether ether ketone (PEEK) is a critical property that influences its performance in various engineering applications. Several key factors affect this characteristic, including molecular structure, temperature, and humidity levels. The molecular arrangement of PEEK contributes significantly to its ability to withstand electric fields without failure. The presence of crystalline regions within the polymer can enhance its dielectric properties, resulting in higher dielectric strength. As temperature increases, however, the dielectric properties may change, necessitating careful consideration of thermal stability in application-specific environments.

Moreover, environmental conditions such as humidity significantly impact the dielectric strength of PEEK. Increased moisture content can lead to dielectric breakdown and reduced insulation performance. It is essential for engineers to evaluate the operational environment and incorporate appropriate measures to mitigate the effects of humidity. Additionally, factors like processing conditions and the presence of additives can also play a pivotal role in modifying the dielectric properties of PEEK, leading to enhanced performance in electrical insulation applications. Understanding these key factors is crucial for optimizing the use of PEEK in high-performance engineering solutions.

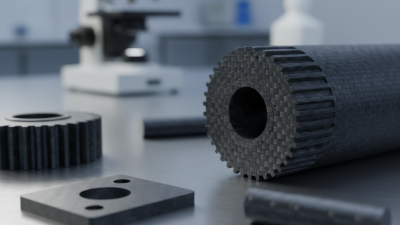

The dielectric strength of Peek, a high-performance thermoplastic, stands out when compared to various other materials used in electrical insulation. Dielectric strength refers to a material's ability to resist electrical breakdown under stress, making it a crucial property for applications involving high voltage and extreme environments. Peek exhibits exceptional dielectric strength, often outperforming traditional insulating materials such as polyimide and silicone. This superior performance can be attributed to its crystalline structure and high thermal stability, allowing Peek to maintain its insulating properties even at elevated temperatures.

Comparative analysis reveals that while materials like polypropylene and PVC are commonly used due to their cost-effectiveness, they fall short in terms of dielectric strength and thermal resistance. The unique characteristics of Peek, such as low moisture absorption and excellent mechanical properties, enable it to serve critical functions in applications ranging from aerospace to medical devices. This makes Peek not only a robust choice but also a reliable one when high dielectric strength is required alongside other performance criteria. As industries continue to evolve, the demand for advanced materials like Peek will likely increase, solidifying its position as a leader in dielectric applications.

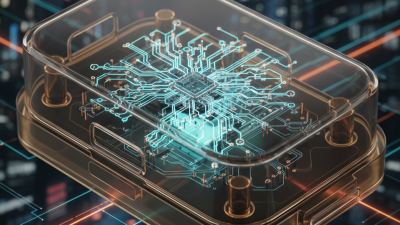

The dielectric strength of polyetheretherketone (PEEK) has gained significant attention in advanced technology sectors due to its superior electrical insulation properties. This characteristic is particularly beneficial in applications requiring reliable performance under high-stress conditions, such as aerospace, automotive, and medical devices. In aerospace, PEEK's ability to withstand extreme temperatures and aggressive environments makes it an ideal candidate for insulators in electrical wiring and components, ensuring safety and functionality throughout a vehicle's lifecycle.

In the automotive sector, PEEK’s dielectric strength plays a critical role in the development of electric and hybrid vehicles. As the industry shifts towards electrification, materials that can endure elevated voltages and provide efficient insulation are essential. PEEK's thermal stability and resistance to wear complement its electrical properties, making it suitable for components in electric drivetrains, sensors, and battery systems. Furthermore, in the medical field, PEEK is increasingly employed for implantable devices due to its biocompatibility and dielectric performance, which support the reliability and longevity of devices used in sensitive applications like neurostimulation and prosthetics.

The integration of PEEK in these advanced technology sectors highlights the ongoing innovation in material science, paving the way for more efficient and durable solutions in the face of evolving engineering challenges. As industries continue to explore the potentials of high-performance materials, PEEK stands out for its versatility and high dielectric strength.

The application of PEEK (Polyether Ether Ketone) materials is rapidly evolving, particularly in industries demanding high-performance dielectric solutions. As measurements of dielectric strength become more critical, innovations in measurement techniques are paving the way for greater accuracy and efficiency. The 2022 Industry Analysis report indicated a significant growth forecast in the PEEK market, expected to expand by 6.5% annually, driven by advancements in material science and engineering.

Future trends suggest that incorporated technologies such as Artificial Intelligence (AI) and machine learning will play pivotal roles in improving dielectric strength testing methods. Enhanced data analytics can provide deeper insights into the dielectric properties, while automated equipment can ensure consistent and reliable measurements. According to recent studies, high-precision dielectric testing can lead to performance improvements of up to 20% in high-stress environments, showcasing the importance of these innovations.

Tip: When evaluating dielectric strength measurement techniques, consider adopting sensors with higher sensitivity and automation capabilities. This can mitigate human error and improve overall measurement accuracy, leading to more reliable applications. Furthermore, regular updates on the latest testing standards can ensure compliance with industry requirements, keeping your operations ahead of the curve.